Wood Processing

In recent years, Ukraine’s energy sector has been undergoing significant changes, with growing concerns over energy security and reducing dependence on imported fuels. Each year, the demand increases for technologies and raw materials capable of replacing fossil fuels—particularly natural gas.

One of the most popular alternatives in Ukraine is the use of wood in the form of pellets. Today, this is an efficient and environmentally friendly way to utilize renewable resources for energy production. This approach enables a gradual shift away from traditional energy sources, strengthens the resilience of the energy system, and reduces the negative impact on the environment.

What Are Wood Pellets: General Information

Wood pellets are an environmentally friendly type of solid fuel manufactured from compressed wood. This requires specialized equipment including hammer mills, dryers, conveyor systems, and pellet mills. Various materials serve as raw materials in wood pellet production, including logs, slab wood, wood offcuts, shavings, chips, sawdust, and bark. Through specific production stages, the source material is compressed, pressed, and processed into cylindrical granules or pellets. Pellet diameter and length depend on the particular equipment used. In pelleted form, the raw material becomes highly convenient for transportation, easy storage, and versatile applications.

Key Characteristics of Wood Pellets

Although Ukraine's wood pellet manufacturing industry is currently in a development stage, producers should focus on product requirements regulated by ENplus international certification. Meeting these criteria guarantees high pellet quality and helps build consumer confidence in both domestic and European markets.

According to ENplus standards, fuel pellets must have the following characteristics:

|

Characteristic |

Value |

Comment |

|---|---|---|

|

Diameter |

6-8 mm |

Tolerance: ±1 mm |

|

Ash Content |

0,7-1,2% |

Maximum allowable ash content level |

|

Moisture Content |

7-10% |

Maximum allowable moisture level |

|

Bulk Density |

600-750 kg/m³ |

Minimum and maximum bulk density |

|

Mechanical Durability |

up to 98% |

Percentage of remaining pellet mass after screening |

|

Energy Output/Calorific Value |

up to 4.6 kW/kg |

Energy output per kilogram of pellets |

Additionally, you can assess pellet quality independently through visual appearance and physical-chemical properties:

-

Carefully examine the pellets. In packaging, they should be uniform in size with a smooth, glossy surface.

-

Quality pellets should not easily break apart or crumble in your hands.

-

When pellets are submerged in water, they should completely sink to the bottom. This indicates high product density.

-

Quality pellets should not leave color residue when handled, demonstrating the absence of dyes and other artificial additives in their composition.

-

The presence of numerous damaged or broken pellets in packaging may indicate potential issues in the manufacturing process.

Advantages of Using Fuel Pellets

Pellets are a highly popular fuel type among both Ukrainian consumers and the European market. This widespread popularity stems from several significant factors:

-

Eco-friendliness. The raw material contains no glues, oils, or other harmful substances, so combustion releases no toxic compounds into the atmosphere. This makes pellets completely safe for environment.

-

Efficiency. Pellets deliver high heat output during combustion. When burned, they produce no carbon dioxide emissions, generate no odor, and burn completely without residue.

-

Economic benefits due to affordable raw material costs. They offer better value compared to other fuel types such as charcoal, natural gas, or electricity.

-

Practicality. Wood waste previously considered unusable is now transformed into fuel pellets, giving it a new, beneficial purpose.

-

Compactness. Pelleted material takes up minimal space, has no odor, and creates no mess or debris. These properties make pellets convenient for storage under any conditions.

-

Convenience. Uniform pellets have excellent flow characteristics, allowing for packaging in various batch sizes and automated feeding to any designated equipment.

Stages of Wood Pellet Manufacturing

Today, wood fuel pellets are gradually gaining demand among both household and industrial consumers. Proportional to this demand, the number of companies manufacturing this product is also growing. To obtain a high-quality product, it's important not only to purchase a quality pellet mill from a reliable equipment supplier, but also to understand what stages comprise the complete production cycle.

We propose familiarizing yourself with the key stages of the pellet manufacturing process. This will help better understand the properties of this fuel type and ensure high efficiency at each stage of its production:

-

Primary raw material grinding. The initial stage involves crushing wood waste in a hammer mill to obtain fractions no larger than 15×10×10 mm. This is necessary for maximum drying efficiency before subsequent grinding.

-

Drying. If the raw material has high moisture content, it's dried using a dryer to improve pressing and pellet quality. Drying reduces moisture content to 7-11%, with 10% considered optimal.

-

Secondary raw material grinding. Ready-to-press material is ground to the required size. We recommend using a hammer mill capable of very fine grinding of raw materials: wood shavings, sawdust, etc. Depending on fractions, quality equipment allows obtaining approximately 150-200 kg of raw material per cubic meter.

-

Pellet pressing. A crucial stage where pellet mills with dies are used for pressing raw materials. Depending on the die type, pellets have specific shape and size. It's important to understand that the die is the pellet mill's main component, and it must be properly selected for each raw material type. Therefore, when choosing this component, it's important to consider hole thickness and diameter.

-

Product cooling. Since pelletizing occurs at high temperatures reaching 75-90°C, pellets fresh from the press are cooled and dried using a pellet cooler. This ensures stable pellet quality before packaging and shipping.

-

Packaging. Finished pellets are packaged in polyethylene bags according to production standards. For warehouse storage, we recommend using bins or dry, dark rooms. This preserves biofuel quality over extended periods and enables convenient use for its intended purpose.

Where to Buy Pellet Mills in Ukraine

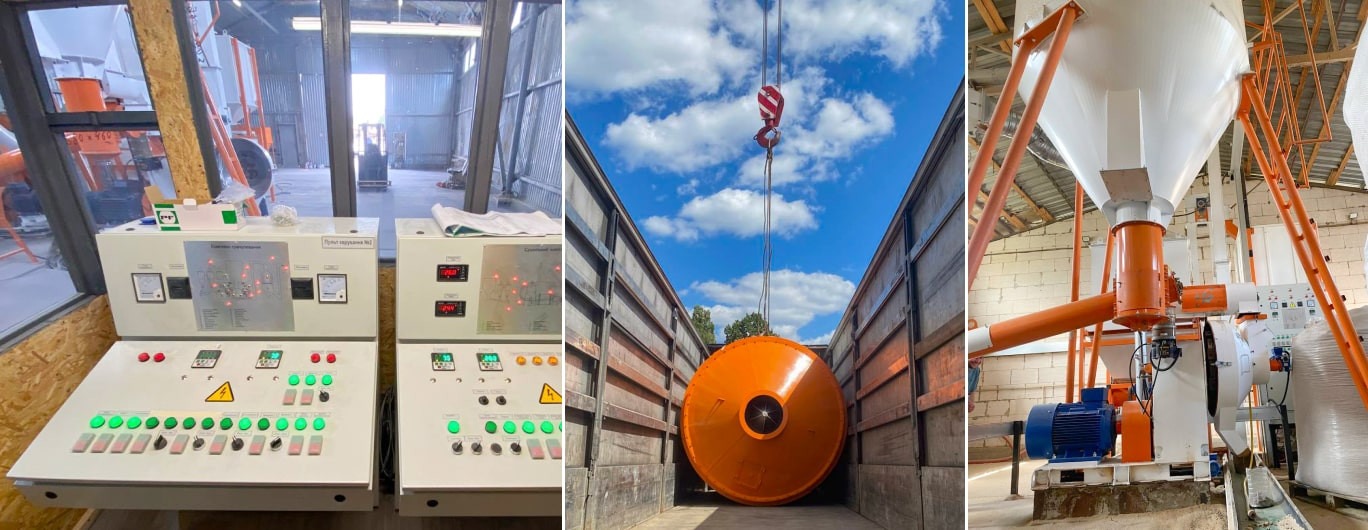

"UKRBIO TRANS-SERVICE" manufactures pellet mills and offers equipment for pellet production at the best prices in Ukraine.

Through continuous implementation of innovative production processes, our pelletizing equipment has the following advantages:

-

Maximum power and productivity — achieved through quality materials that ensure long-term, uninterrupted operation under various external conditions;

-

Energy efficiency — smart energy consumption due to in-house developments and systems that convert input energy into useful output as efficiently as possible, reducing energy loss;

-

Process automation — ensures thorough production control through automated control systems. This guarantees high product quality — uniformity, optimal shape, and exceptional characteristics;

-

Simple equipment operation thanks to an intuitive and user-friendly interface;

-

Ability to use different die types with various diameter fractions, making our equipment flexible and easily adaptable to production processes;

-

Quality equipment at competitive prices from a Ukrainian manufacturer.

Advantages of Partnering with Our Company

As part of pellet mill servicing, "UKRBIO TRANS-SERVICE" offers the following:

-

Proper die selection for each raw material type to ensure optimal pelletizing results. When necessary, we offer die replacement;

-

Selection of appropriate pellet mill capacity that matches the specific type of raw material being processed;

-

Efficient setup of the raw material grinding process to ensure high pellet quality;

-

Technical audits and equipment commissioning to ensure the most efficient operation in production;

-

Training on equipment operation and optimal use to maximize productivity;

-

Provision of technical documentation and all necessary warranties;

-

Careful delivery of our equipment to any region of Ukraine;

-

Individual financial terms and flexible cooperation considering each client's specific needs.

Our company is engaged not only in manufacturing and supplying equipment, but also provides a full range of services for successful operation of your production:

-

Plant Design. With our own manufacturing capabilities and years of experience, we offer development of efficient solutions for production facilities in the pellet manufacturing industry.

-

Plant Upgrade. We provide implementation of cutting-edge technologies to increase productivity, efficiency, and production quality.

-

Pellet Mill Repair. The high qualifications of our specialists allow us to perform equipment repairs at production sites regardless of complexity, ensuring reliable and uninterrupted operation.

-

Maintenance Service. We provide complete service support for our clients, including consultations and regular technical assistance for efficient pellet production.

Contact us via the phone numbers on our website, and we guarantee high quality standards, professionalism, and mutually beneficial cooperation.